Bewitagos1

Well-known member

RD/Steve said:by the looks of all that, it might have been the bolts from the transformer that caused an arch inside the chassis.

regardless...contact service at 847-643-5120. they will be bale to help you out.

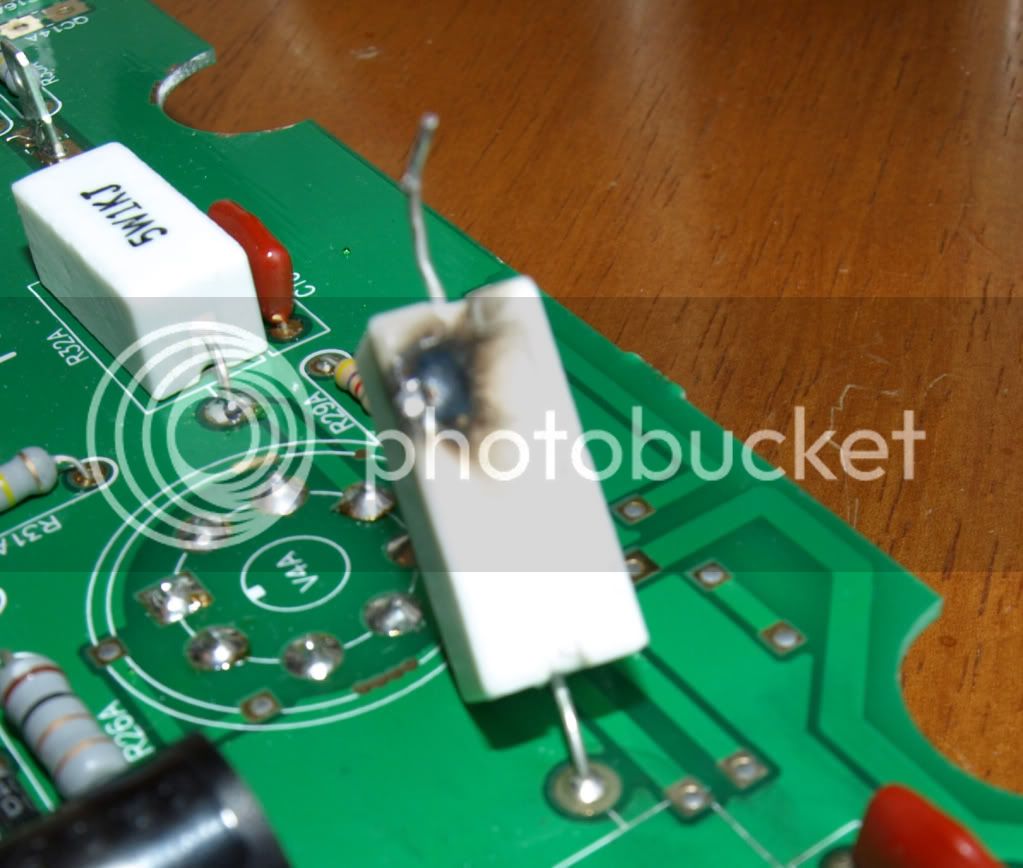

Steve, your diagnoses was correct with arcing, but the culprit wasn't the washer or nut from the Transformer. The bottom of the resistor has solder etched into it. (see photo below) I've had this problem in the past with circuit boards we farmed out to have wave soldered, either too much or too little solder pushed up through to the component side of the circuit board when the machine wasn't set up correctly or the circuit board had cleaning or inherent design issues.

In this case, the excess solder pooled over the foil under the resistor. it passed QC because the short hadn't occurred until I ramped up the current. Capacitance between the plate and ground occurred until the heat finally broke down the foil and you all had to suffer with my insistent quest for an answer.